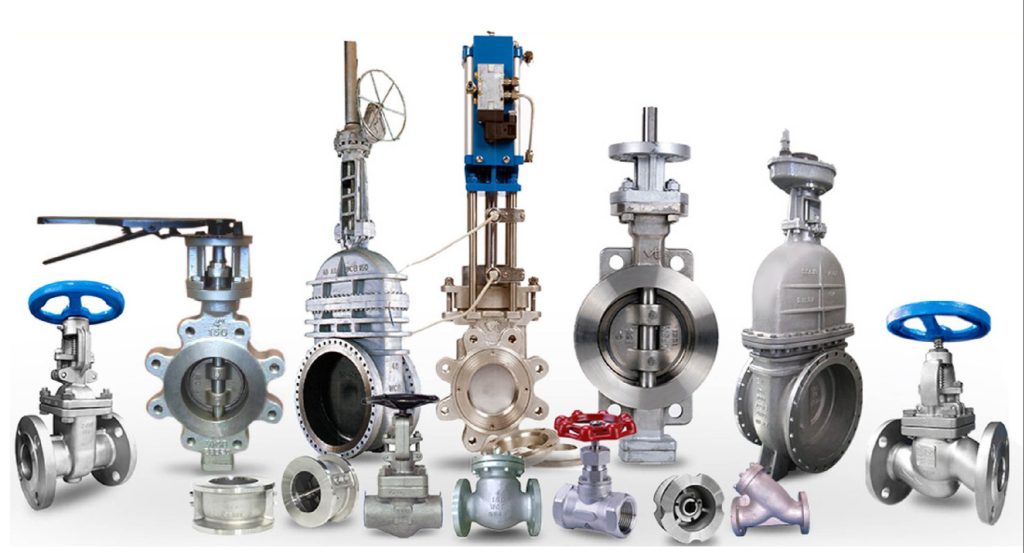

Industrial Valves along with their accessories

Industrial valves are devices used to control the flow of fluids (liquids or gases) in various industrial processes. They are essential components in pipelines, vessels, and other systems, allowing operators to start, stop, regulate, or divert the flow of the media. Valves come in different types and configurations to suit specific applications and process requirements.

Some common types of industrial valves include:

1. Gate Valves: Gate valves have a sliding gate or wedge that moves perpendicular to the flow path, allowing full flow when open and tight shut-off when closed.

2. Globe Valves: Globe valves have a disc that moves up and down perpendicular to the flow path to regulate or control the flow.

3. Ball Valves: Ball valves have a spherical disc with a hole in the center that rotates to allow or block the flow.

4. Butterfly Valves: Butterfly valves have a disc that rotates around an axis to control the flow.

5. Check Valves: Check valves allow flow in one direction only, preventing backflow or reverse flow.

6. Diaphragm Valves: Diaphragm valves use a flexible diaphragm to regulate flow.

7. Plug Valves: Plug valves have a cylindrical or conical plug that rotates to control the flow.

8. Pinch Valves: Pinch valves use a pinching mechanism to control flow by pinching or releasing a flexible tube or sleeve.

9. Pressure Relief Valves: Pressure relief valves protect systems from overpressure by releasing excess pressure.

10. Safety Valves: Safety valves protect systems from excessive pressure by opening automatically when a set pressure is exceeded.

Industrial valve accessories are supplementary components that enhance the performance or operation of the valves. Some common valve accessories include:

1. Actuators: Actuators are used to automate valve operation, converting control signals into mechanical motion to open or close the valve.

2. Positioners: Positioners adjust the valve position based on control signals to achieve precise flow control.

3. Valve Position Indicators: Valve position indicators provide visual or electronic feedback on the valve’s current position.

4. Limit Switches: Limit switches provide electrical signals when the valve reaches a fully open or fully closed position.

5. Solenoid Valves: Solenoid valves are electrically operated valves used to control the flow automatically.

6. Valve Lockouts: Valve lockouts are used for safety purposes to lock valves in a specific position to prevent accidental operation.

7. Valve Stem Extensions: Valve stem extensions are used to extend the valve stem for operation in hard-to-reach locations.

8. Valve Positioners: Valve positioners are used to accurately control the valve position based on control signals.

These accessories add functionality, control, and safety to the industrial valve systems, making them efficient and reliable components in various industrial processes.